Magnaflow’s New Oceanside Tech Center: Keeping the Cutting-Edge Sharper Than Ever

Magnaflow is a company that is always growing and changing. It is constantly innovating with new products and technologies that help to keep it at the forefront of the industry. When it moved its corporate office to Oceanside, Magnaflow doubled down on its commitment to remain a staunchly Californian company, but it also created challenges since its development and tech center was still nearly 50 miles away in Rancho Santa Margarita. As of March 2017, Magnaflow has finally finished construction on its new and improved tech center and we’re going to share a little about what’s changed.

The first big change is that Magnaflow swapped out its old two-wheel drive dyno for a more modern and accurate four-wheel drive eddy current dyno. This will allow more accurate power readings for performance exhaust systems and help with even more accuracy for emissions tests for catalytic converters. Next is a vastly expanded and state-of-the-art metrology department with the very latest blue-light laser scanning equipment as well as a variety of rapid prototyping tools which will ensure the quickest and most efficient development cycle possible, with no sacrifice in terms of quality or accuracy.

For new vehicles, the blue-light technology allows MagnaFlow to scan the underside of each vehicle quickly and accurately to get a look at the layout of the factory exhaust system to easily layout an aftermarket system before engineers even touch a welder.

Another large part of the move was creating a new campus concept for the MagnaFlow team. Adding the research and development and administrative teams to the 10 year veteran building housing the manufacturing facility gave the MagnaFlow team a deeper unity by maximizing the proximity to each team for even better collaboration. Additionally, as it expands into other exhaust and performance segments, it will have the ability to add on with the land surrounding the facility. This is a consolidation of several facilities throughout Southern California and should dramatically impact the efficiency of production.

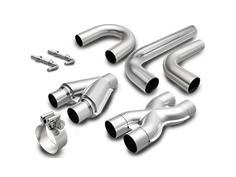

Among the applications already designed in this new facility are full stainless performance systems for the 2017 Ford Raptor, 2017 Camaro SS/L4/V6, 2017 Nissan Titan XD and 2017 BMW M2, as well as systems for V-Twin applications. If the quality of these systems is any indication of what to expect from Magnaflow in the future, there are great things on the horizon.

Comments