CATALYTIC CONVERTER BASICS

MAGNAFLOW CATALYTIC CONVERTER QUALITY:

Compare MagnaFlow's catalytic converters with any other manufacturer and you’ll see why MagnaFlow has become a leader in the manufacturing of exhaust components. Others may employ one or two of the following features, but only MagnaFlow puts them all together to create a catalytic converter that exceeds basic need and function. Our years of research and development have resulted in many unique features that are exclusive to MagnaFlow. We combine efficient manufacturing techniques and state-of-the-art industrial design to produce an end process and product that sets, rather than meets, the highest standards of product performance and

efficiency in the industry.

|

|

|

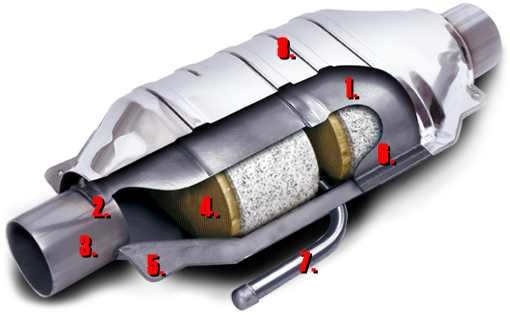

1. MagnaFlow converters have a ribbed body that minimizes expansion and distortion when the converter heats up. The ribs form a channel that protects the cushioning mat from direct exposure to exhaust gasses and they hold the ceramic catalyst in proper alignment.

|

|

2. MagnaFlow converters have a 1/2” lap-joint where the necks meet the body. The neck does not extend into the converter body where it could hamper exhaust flow. This is the strongest and smoothest flowing inlet/outlet joint of any manufacturer.

|

|

3. We maintain separate dies on different sized inlets. We don’t skimp by putting larger neck sizes on smaller bodies. This would reduce the flow of the converter and reduce the quality of our product.

|

|

4. MagnaFlow uses a monolithic honeycomb catalyst. The ceramic is designed for maximum flow and surface area. The coating method is strictly controlled to maintain exact specifications. An improper coating could result in flow restrictions or an emission test failure.

|

|

5. MagnaFlow uses a heavier gauge stainless steel, tip to tip. Others use mixed weights and materials.

|

|

6. MagnaFlow converters are seam welded close to the converter body for a strong, tight bond. We don’t weld along the edge which could allow the converter to expand like the folds in an accordion, allowing the catalyst to move around.

|

|

7. MagnaFlow installs a factory capped, 90 degree air tube on “with air” converters. This saves time during installation. There is no need for additional labor to weld on an air tube or to create a bend when only an air tube stub is provided.

|

|

8. MagnaFlow uses an aluminized or stainless OEM-style ribbed heat shield that creates a rigid wall of protection against heat and adds to the structural stability of the converter.

|

|

Clean Parts - MagnaFlow de-greases and washes all fabricated components after assembly. The new converter is clean of metal dust and fragments. Every converter comes out of the box clean. This is almost an exclusive feature of MagnaFlow.

|

|

Resealable Boxes - MagnaFlow’s converter boxes are made of a heavy gauge corrugated board that is three layers thick at the ends to protect the converters during shipment. The boxes are easily opened and re-closed, keeping the customer’s inventory looking better, longer. Known throughout the industry as “the pizza box,” it is yet another example of how we set ourselves apart from competitors.

|